The machining industry is evolving rapidly as manufacturers face pressure to deliver higher precision, faster lead times, and increased efficiency—without compromising on quality. At VertX Manufacturing, we keep a close eye on industry trends so we can adapt and continue to deliver best-in-class service to our customers. Here’s a look at the top machining trends defining 2025:

1. Rise of Smart Manufacturing & Industry 4.0 Integration

Digital transformation is no longer optional—it’s a necessity. Machine shops are increasingly integrating IoT sensors, AI, and real-time analytics into operations. This enables smarter decision-making, predictive maintenance, and better resource allocation. At VertX, we’re leveraging data to reduce downtime and improve part accuracy.

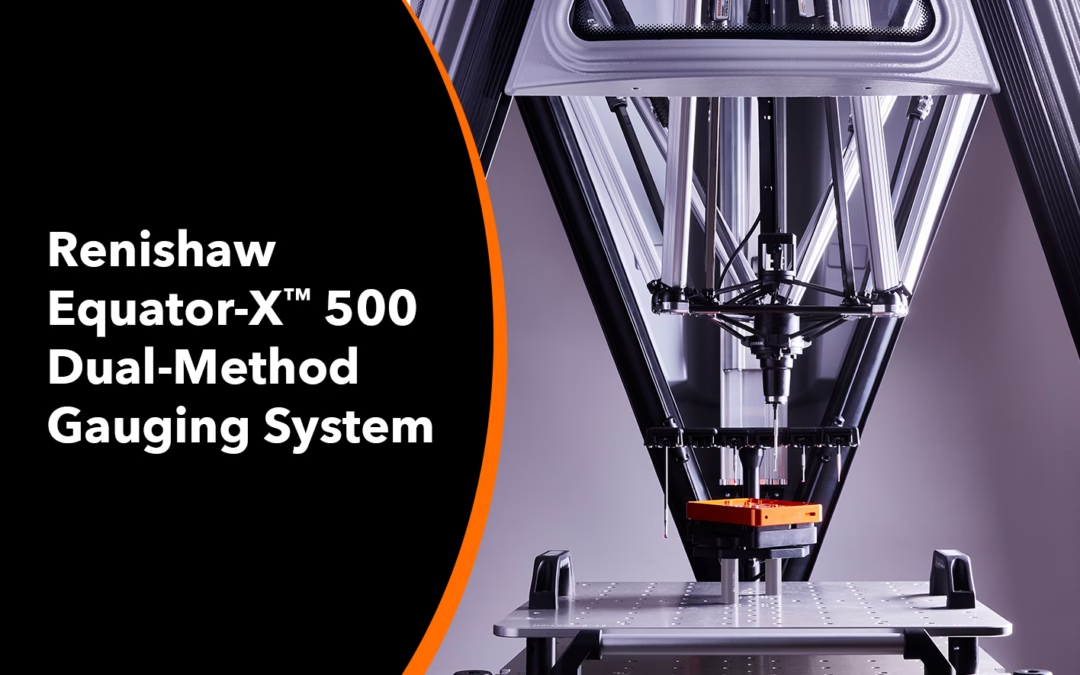

2. Automation & Lights-Out Machining

Labor shortages and the need for around-the-clock production have fueled the rise of automation and lights-out manufacturing. Robotic arms, pallet changers, and automated tool management systems allow machines to run unattended during off-hours, increasing productivity without increasing labor costs.

3. Advanced Materials Driving Demand for Specialized Machining

As aerospace, defense, and medical industries adopt more advanced and exotic materials, machining them requires tighter tolerances and more specialized tooling. VertX continues to invest in equipment and training that allows us to handle difficult-to-machine materials like Inconel, titanium, and hardened stainless steels.

4. Additive Manufacturing Meets Traditional Machining

Hybrid manufacturing—combining additive (3D printing) with traditional subtractive methods—is becoming a practical solution for prototyping, tooling, and even production. VertX has implemented additive technologies for custom packaging and workholding solutions, helping protect critical parts and reduce damage during transit.

5. Reshoring & Supply Chain Resilience

Supply chain disruptions and rising overseas labor costs have pushed many companies to reshore manufacturing. With a growing focus on American-made quality and shorter lead times, CNC shops like VertX are well-positioned to support this shift by offering reliable, domestic production.

6. Focus on Sustainability & Waste Reduction

Sustainability is becoming a core consideration in machining. Shops are looking to reduce scrap, energy consumption, and coolant waste through smarter programming, tool management, and material utilization. VertX takes pride in optimizing processes to minimize waste while maximizing quality.

7. Increased Emphasis on Workforce Development

With the skills gap widening, manufacturers are doubling down on training, apprenticeships, and cross-functional roles. At VertX, we’re not just building parts—we’re building careers by investing in our team and offering on-the-job training for motivated individuals.

Final Thoughts

As the industry changes, one thing stays the same: our commitment to precision, reliability, and service. VertX Manufacturing is dedicated to staying ahead of the curve, investing in the future, and delivering for our customers no matter what challenges 2025 brings.

Let’s talk about how these trends could affect your next project. Contact us today to see how VertX can be your trusted partner in this rapidly evolving landscape.