In the world of precision manufacturing, tight tolerances are more than just a specification—they’re a necessity. Whether in aerospace, medical, automotive, or defense industries, even the slightest deviation from required measurements can mean the difference between success and failure. At VertX Manufacturing, we understand that quality and precision go hand in hand, which is why we prioritize tight tolerances in every project we take on.

What Are Tight Tolerances?

Tolerances refer to the allowable variation in a part’s dimensions. The tighter the tolerance, the less deviation is permitted. In high-performance applications, tolerances often fall within ±0.0005 inches, ensuring components fit and function flawlessly. These ultra-precise measurements are critical in industries where performance, reliability, and safety are paramount.

Why Do Tight Tolerances Matter?

Performance & Reliability

Parts with tight tolerances ensure seamless functionality in complex assemblies. Whether it’s a medical implant, an aerospace component, or an automotive part, even the smallest inconsistency can compromise performance and safety.

Interchangeability

In large-scale production, every component must fit perfectly into its designated system. Tight tolerances allow for parts to be interchangeable, reducing downtime and improving efficiency in manufacturing processes.

Enhanced Product Longevity

Poorly machined parts can lead to premature wear and failure. By maintaining strict tolerances, high-performance components experience less friction, wear, and stress—extending their lifespan and improving overall durability.

Cost Efficiency

While achieving tight tolerances requires expertise and high-quality machining equipment, it ultimately reduces costs by minimizing rework, material waste, and product failure rates.

Achieving Tight Tolerances at VertX Manufacturing

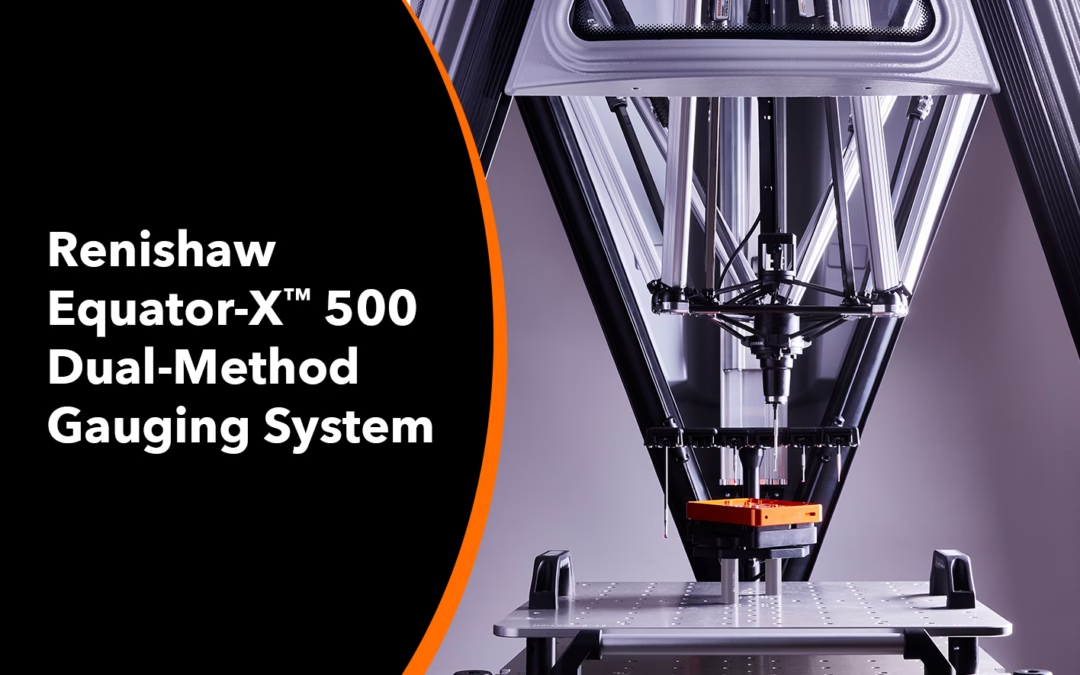

At VertX Manufacturing, we leverage state-of-the-art CNC machining technology and rigorous quality control processes to ensure tight tolerances on every part we produce. Our advanced multi-axis machines allow for precise, multi-dimensional machining, reducing errors and increasing accuracy.

Additionally, our quality assurance team implements in-depth inspections, utilizing coordinate measuring machines (CMMs) and laser scanning technology to verify accuracy at every stage of production.

Choosing a Manufacturing Partner for Precision Parts

Not all manufacturers can consistently achieve the tight tolerances required for high-performance parts. When selecting a machining partner, it’s essential to consider:

Experience & Expertise: Look for a manufacturer with a proven track record in precision machining.

Technology & Equipment: Advanced CNC machines and metrology tools are critical for maintaining tight tolerances.

Quality Control Measures: Consistent inspections and certifications to ensure adherence to strict industry standards.

Final Thoughts

Quality isn’t just about meeting specifications—it’s about delivering reliable, high-performance parts that drive innovation. At VertX Manufacturing, we take precision seriously, ensuring that every part we produce meets the highest standards of quality and accuracy.

Looking for a machining partner that prioritizes precision? Contact VertX Manufacturing today to discuss your next project and discover how we can help you achieve the tight tolerances you need for success.